4nm - The Chip The Tech World’s Been Waiting For

A 4nm chipset seems to be something futuristic. Well, the future is here, and several smartphones in 4nm have already been recently released (with more to come). While the benefits of smaller chips/transistors are plenty, note that there can be disadvantages, too.

Author:Darren McphersonReviewer:Gordon DickersonApr 18, 202340.7K Shares1.1M Views

4nmrefers to the manufacturing process node used in the production of semiconductor chips.

It is a technology node that is currently under development and is expected to be available for mass production in the near future.

The “nm” stands for nanometers, which is the unit used to measure the size of transistors and other components on a semiconductor chip.

The smaller the size of the components, the more of them can be packed onto a chip, leading to greater processing power, lower power consumption, and other benefits.

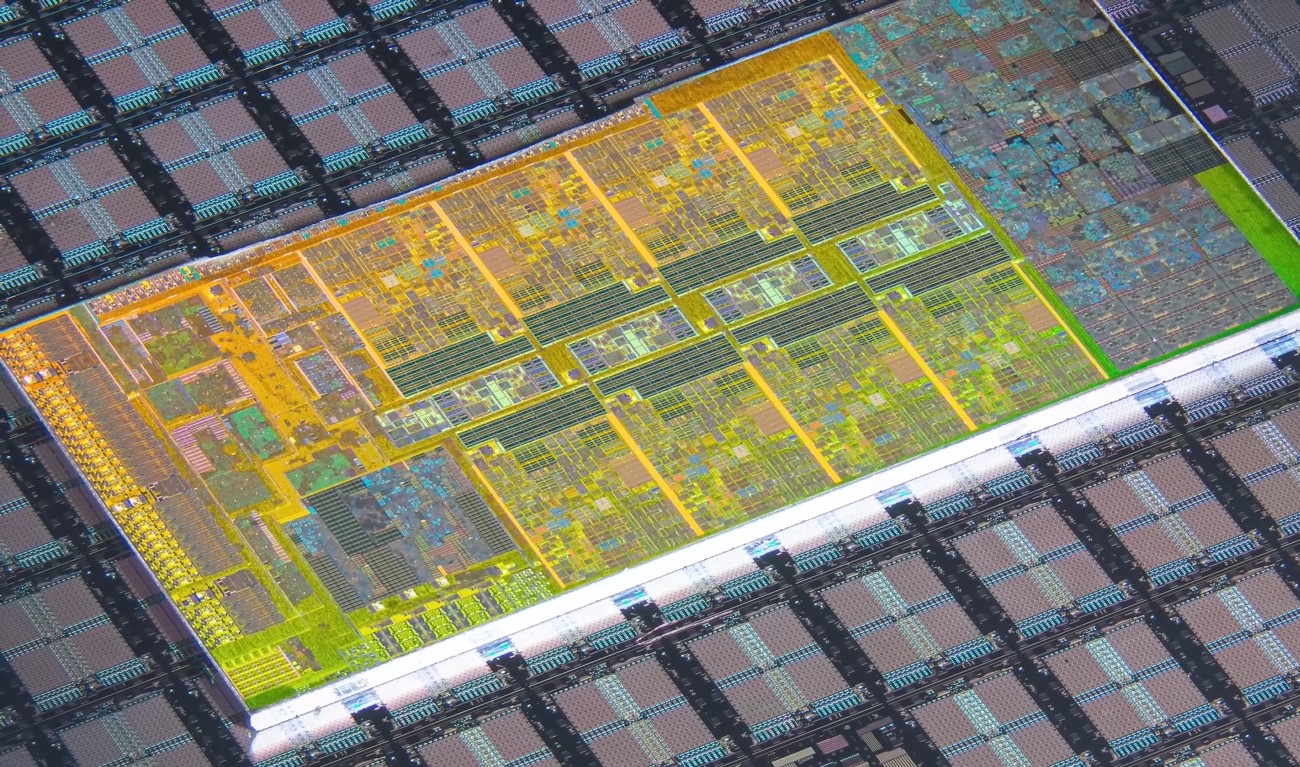

The World's First 4nm-class Smartphone Chip

4nm Chip

The “4nm” designation refers to the manufacturing process technology used to fabricate the chip, which represents the distance between transistors on the chip.

It does not necessarily reflect the actual size of the transistors or the performance of the chip.

Several semiconductor companies have announced plans to develop and produce 4nm chips in the near future. They include:

- Intel (U.S.)

- Samsung (South Korea)

- TSMC (Taiwan)

Apple 4nm Chip

There have been reports that Apple is planning to release a 4nm chip in the near future.

In fact, in July 2021, it was reported that TSMC had started mass production of 4nm chips for Apple’s upcoming devices.

By the way, Taiwan Semiconductor Manufacturing Company (TSMC) is the company that manufactures chips for Apple.

Phone Arena, in a September 2022 article, quoted Apple as saying that its A16 Bionic, with “4nm manufacturing,” is:

“„Focused on three main areas: power efficiency, display, and camera. The new CPU is 40 percent faster than the competition.- Apple

It is expected that the 4nm chip will be used in the next generation of Apple’s A-series processors, which power the iPhoneand iPad.

4nm Comparison

The 4nm process node is expected to offer significant improvements over current technology nodes, such as 7nm or 5nm, in terms of power efficiency, performance, and transistor density.

4nm VS 5nm

The difference between 4nm and 5nm refers to the size of the transistor technology used in the manufacturing process of computer chips.

As mentioned earlier, the smaller the transistor size, the more transistors can be packed onto a single chip, leading to increased processing power and energy efficiency.

In general, a 4nm chip is expected to have more transistors than a 5nm chip, which translates into better performance and power efficiency.

However, the difference in performance and power consumption may not be significant enough to justify the cost of upgrading from a 5nm chip to a 4nm chip.

Why? It’s because the manufacturing process becomes more complex and expensive with each decrease in transistor size.

4nm VS 6nm

4nm and 6nm refer to the process node size used in the manufacturing of computer processors and other integrated circuits.

When comparing 4nm and 6nm, the main difference is that 4nm is a smaller process node size than 6nm.

This means that chips manufactured using a 4nm process are likely to be more power-efficient and have better performance than those manufactured using a 6nm process.

Nonetheless, it’s worth noting that the difference in performance and power efficiency may not be significant, as the two process node sizes are relatively close together.

4nm VS 7nm

4nm and 7nm are both semiconductor manufacturing technologies used to produce advanced computer chips.

The main difference between the two is their transistor density, which is a measure of how many transistors can be packed into a given area on a chip.

In general, the smaller the manufacturing process, the higher the transistor density, and the more powerful and energy-efficient the resulting chips are.

This is because smaller transistors can switch faster and require less power to operate, which allows for higher clock speeds and lower energy consumption.

At 4nm, the transistor density is expected to be around 171.3 million transistors per square millimeter, while at 7nm it is around 91.2 million transistors per square millimeter.

This means that 4nm chips are likely to be more powerful and energy-efficient than 7nm chips, all other things being equal.

Still, while 4nm is expected to be an improvement over 7nm, it’s not a guaranteed or absolute difference in performance.

Advantages Of Small NM Chip

A small nm (nanometer) chip refers to a microchip manufactured using a process technology that produces transistors and other components with dimensions measured in billionths of a meter.

The advantages or benefits of small nm chips include:

1. Increased Performance

The smaller the size of the transistors on a chip, the faster they can switch on and off, allowing for faster data processing and improved performance.

2. Lower Power Consumption

Small nm chips such as 4nm chips require less power to operate, making them more energy-efficient and helping to prolong battery life in portable devices.

3. Higher Density

Smaller transistors on a chip:

- allows a greater number of components to be packed onto the same size chip

- increases the density of the circuitry

- provides room for more features and functionality

4. Cost Reduction

With smaller transistors, chip manufacturers can produce more chips per wafer, reducing the overall cost per chip.

5. Miniaturization

Small nm chips enable the creation of smaller and more compact devices, which is especially useful in applications such as:

- mobile devices

- wearables

- Internet of Things (IoT) devices

Overall, 4nm and similar small nm chips make them highly desirable for a wide range of applications in various industries.

What Happens When Transistors Get Too Small?

It seems that at least three giant technology companies already expressed interest in manufacturing 4nm chips.

As transistors continue to shrink in size, however, several technical challenges arise. Some of these challenges include:

a. Leakage current

As transistor size decreases, the distance between the source and drain decreases, which can lead to increased leakage current.

Leakage current is the flow of electrons between the source and drain even when the transistor is turned off. This can lead to increased power consumption and reduced battery life.

b. Gate oxide thickness

The gate oxide is the insulating layer between the gate and channel of a transistor. As the transistor size decreases, the gate oxide thickness must also decrease.

However, as the gate oxide thickness becomes thinner, it becomes more difficult to control the flow of electrons through the transistor.

c. Short channel effects

As transistor size decreases, the length of the channel between the source and drain decreases.

This can lead to short channel effects, which can cause variations in the transistor’s behavior and make it more difficult to control the flow of electrons through the transistor.

d. Electromigration

As transistors become smaller, the current density in the metal interconnects increases.

This can cause electromigration, which is the movement of atoms in the metal interconnects due to the flow of current.

Electromigration can lead to the failure of the interconnects and reduce the reliability of the transistor.

e. Heat dissipation

As transistor size decreases, the density of transistors on a chip increases.

This can lead to increased heat generation, which can make it more difficult to dissipate the heat and can lead to increased power consumption and reduced reliability.

f. Manufacturing challenges

As transistor size decreases, the manufacturing process becomes more complex and requires more precise control over the fabrication process.

This can lead to increased manufacturing costs and reduced yield.

IBM's 2nm transistors could supercharge your phone (in a few years) | Upscaled Mini

People Also Ask

Is Snapdragon A 4nm Processor?

The 4nm process of the Foundry Division - a semiconductor manufacturer - of Samsung Electronics paved the way for the mobile processor Exynos 2200 and Qualcomm’s smartphone chipset Snapdragon 8 Gen 1, according to an updated December 2021 article by SamMobile.

On its website, Qualcomm describes its Snapdragon 8+ Gen 1 Mobile Platform as a “premium-tier powerhouse.”

Which Phones Have 4nm Processor?

Below are some of the smartphones with 4nm chipset, as listed by Deep Specs:

| Smartphone | Date of Release (per GSMArena.com) |

| Asus ROG Phone 6D | October 2022 |

| Honor 80 Pro Flat | January 2023 |

| Motorola ThinkPhone | January 2023 |

| OnePlus Nord 3 | expected: June 2023 (per 91mobiles.com) |

| Oppo Find X6 & Find X6 Pro | both March 2023 |

| Realme GT3 | expected: April 2023 |

| Samsung Galaxy S23 Ultra | February 2023 |

| Vivo V27 Pro | March 2023 |

| Xiaomi Civi 3 | expected: April 2023 (per 91mobiles.com) |

| ZTE Nubia Red Magic 8 Pro & Pro+ | both December 2022 |

Can There Be 1nm Chip?

Research in the field of nanotechnology is ongoing, and it is possible that new breakthroughs in materials and manufacturing processes could enable the creation of 1nm chips in the future.

According to IBM Research, it’s “possible.” In an article published in December 2022, the company’s researchers said:

“„We have identified two major breakthroughs that we believe will lead us down a path to designing computer chip nodes targeting for 1nm and beyond.- IBM researchers

They presented their ideas at the 2022 International Electron Devices Meeting (IEDM 2022) held in San Francisco (December 2-8).

Final Thoughts

The process node size (e.g., 4nm) refers to the size of the transistors and other components that are etched onto the silicon wafer during the manufacturing process.

It’s also important to note that the exact specifications and capabilities of chips manufactured using these process nodes will depend on the specific design of the chip and other factors beyond just the process node size.

So, while the process node size such as 4nm is an important factor in determining chip performance, it’s not the only factor to consider.

Darren Mcpherson

Author

Darren Mcpherson brings over 9 years of experience in politics, business, investing, and banking to his writing. He holds degrees in Economics from Harvard University and Political Science from Stanford University, with certifications in Financial Management.

Renowned for his insightful analyses and strategic awareness, Darren has contributed to reputable publications and served in advisory roles for influential entities.

Outside the boardroom, Darren enjoys playing chess, collecting rare books, attending technology conferences, and mentoring young professionals.

His dedication to excellence and understanding of global finance and governance make him a trusted and authoritative voice in his field.

Gordon Dickerson

Reviewer

Gordon Dickerson, a visionary in Crypto, NFT, and Web3, brings over 10 years of expertise in blockchain technology.

With a Bachelor's in Computer Science from MIT and a Master's from Stanford, Gordon's strategic leadership has been instrumental in shaping global blockchain adoption. His commitment to inclusivity fosters a diverse ecosystem.

In his spare time, Gordon enjoys gourmet cooking, cycling, stargazing as an amateur astronomer, and exploring non-fiction literature.

His blend of expertise, credibility, and genuine passion for innovation makes him a trusted authority in decentralized technologies, driving impactful change with a personal touch.

Latest Articles

Popular Articles