Go Lean Six Sigma Secrets - From Waste To Wow

Discover the power of efficiency and continuous improvement with go lean six sigma. Uncover key methodologies, tools, and best practices to streamline processes, reduce waste, and achieve optimal performance.

Author:Frazer PughReviewer:Dexter CookeDec 27, 202317.6K Shares384.2K Views

Embark on a transformative journey of organizational excellence with go lean six sigma, a dynamic methodology designed to revolutionize business processes. In an era where efficiency is paramount, Go Lean Six Sigma emerges as a beacon, guiding enterprises towards enhanced productivity and minimized waste.

Rooted in the fusion of Lean and Six Sigma principles, this approach empowers organizations to streamline operations, optimize resources, and deliver unparalleled value to customers.

As we delve into the intricacies of Go Lean Six Sigma, we unveil a roadmap that not only improves process efficiency but also fosters a culture of continuous improvement, setting the stage for sustainable success in today's competitive landscape.

What Is Go Lean Six Sigma?

"Go Lean Six Sigma" is a transformative methodology designed to revolutionize organizational processes and elevate performance. This approach integrates the principles of Lean and Six Sigma, creating a robust framework for businesses seeking operational excellence.

At its core, "Go Lean Six Sigma" aims to eliminate inefficiencies and defects in processes, fostering a culture of continuous improvement. The methodology draws from Lean's focus on minimizing waste and Six Sigma's emphasis on reducing variations, resulting in a comprehensive strategy that addresses both efficiency and quality.

The term "Go Lean" underscores the proactive nature of this methodology, urging organizations to lean into the principles of efficiency and optimization. The structured approach of DMAIC (Define, Measure, Analyze, Improve, Control) provides a roadmap for organizations to identify, analyze, and improve processes systematically.

Go Lean Six Sigma empowers organizations to streamline operations, enhance customer satisfaction, and achieve sustainable success in a competitive landscape. It is not merely a set of tools but a mindset that permeates the organizational culture, encouraging teams to continually assess, refine, and excel in their pursuit of operational excellence.

Go Lean Six Sigma Training

Six Sigma certification online is one of the most popular qualifications that many individuals choose these days. The training focuses on improving business processes through continuous improvement using regression methodologies.

Throughout the course, students will learn how to decrease deviation as much as feasible. As a result, client satisfaction has increased. Many companies value professionals who have these qualities. Six sigma green belt, black belt certification, and master black belt certification are the three levels of the credential.

The Importance Of Six Sigma Training For Employees

Professional Worth

Working on Six Sigma initiatives has a significant impact on personnel. It demonstrates that the individual has a solid awareness of the company requirements. As a result, team leaders who have successfully completed large projects, as well as personnel who work on such initiatives, stand to benefit greatly.

Leadership Characteristics

Six Sigma training assists individuals in advancing to positions of leadership. You can be a change agent in the organization once you have earned your black belt in Six Sigma. You will thereafter be able to lead projects aimed at enhancing business operations.

In other words, it will eventually result in higher-quality products or services for clients. This enables users to gain risk assessment and financial management skills.

Above all, it aids in their advancement to upper management positions. The organization implements a variety of initiatives to instill strong leadership qualities in order to maximize the potential of its personnel.

Employee And Customer Satisfaction

Project implementation success leads to total client satisfaction. As a result, the final product or service will be of high quality. Finally, they direct and motivate all employees to strive toward a single goal, resulting in increased job satisfaction.

The Importance Of Six Sigma Training For Organizations

- Enhanced productivity- Time spent on various tasks should be tracked in order to eliminate idle time wherever possible. In other words, shortening the lead time and increasing efficiency.

- Project timeline reduction - Critical activities are prioritized over non-critical ones. Resources are allocated based on the needs. To put it another way, the Just In Time policy.

- Waste reduction and Quality Control - The seven types of waste are removed from the operations to the greatest extent possible, for example:

- Transportation

- Inventory

- Motion

- Waiting

- Over-production

- Over-processing

- Defects

Cost Savings And Revenue Generation

Most businesses are ignorant of their unsatisfied consumers or potential flaws in their operations. As a result, the firm loses significant business as a result. Nowadays, no consumer has the patience to deal with an underperformer.

Furthermore, Six Sigma training will assist people and businesses in overcoming such challenges by constantly improving the company culture. It will also aid in the formation of a creative, effective, and efficient team for the organization's anticipated growth and development.

Six Sigma also employs SMART (Specific, Measurable, Achievable, Realistic, Time-bound) goals to effectively implement and sustain change.

Advantages Of Using Six Sigma

- You will learn how to use Lean to analyze and enhance processes in order to increase efficiency and eliminate waste.

- You'll also learn how to implement Six Sigma principles and techniques to reduce process variance while improving quality and consistency.

- It will help you with your career progress.

- By reducing process variation and waste, this adds value for customers, employees, and shareholders.

- It will also improve Six Sigma project performance and shorten project timelines.

- You may train your staff in a tried-and-true business improvement methodology, providing them with the tools they need to enhance procedures.

- This will cut costs, enhance efficiency, improve resource utilization, and result in a more lucrative firm. Finally, certified professionals display expertise of Six Sigma, and they are constantly in demand.

Why You Should Get A Lean Six Sigma Certification?

Job Advancement

A Lean Six Sigma certification can help you advance in your job. It demonstrates your knowledge of process improvement approaches, making you an invaluable asset to firms in a variety of industries. With this credential, you become eligible for advancement, higher pay, and more work opportunities.

Lean Six Sigma offers a disciplined framework for boosting efficiency and eliminating waste. Certification provides you with in-depth knowledge of Lean Six Sigma tools, methodologies, and principles. These abilities can be used to expedite procedures, minimize faults, and increase overall quality, making you an invaluable asset to any firm.

Productivity Improvement

The goal of Lean Six Sigma techniques is to improve processes, reduce non-value-added tasks, and increase productivity. You will learn how to identify and eliminate process bottlenecks, reduce cycle times, and increase workflow efficiency by receiving a certification. These abilities can result in significant cost savings and higher customer satisfaction.

Problem-Solving Skills

Lean Six Sigma provides you with problem-solving approaches and statistical tools like as DMAIC (Define, Measure, Analyze, Improve, Control). These strategies allow you to pinpoint the source of a problem, analyze data, and make data-driven decisions. A Lean Six Sigma certification teaches you how to solve difficult business problems and drive continuous improvement.

Lean Six Sigma approaches are focused on attaining operational excellence and driving organizational transformation. By acquiring a certification, you become a beneficial force in your workplace.

You may drive a culture of continuous improvement by leading improvement efforts, engaging teams, and driving a culture of continuous improvement. Your knowledge of Go Lean Six Sigmawill help you boost efficiency, cut costs, and improve customer satisfaction.

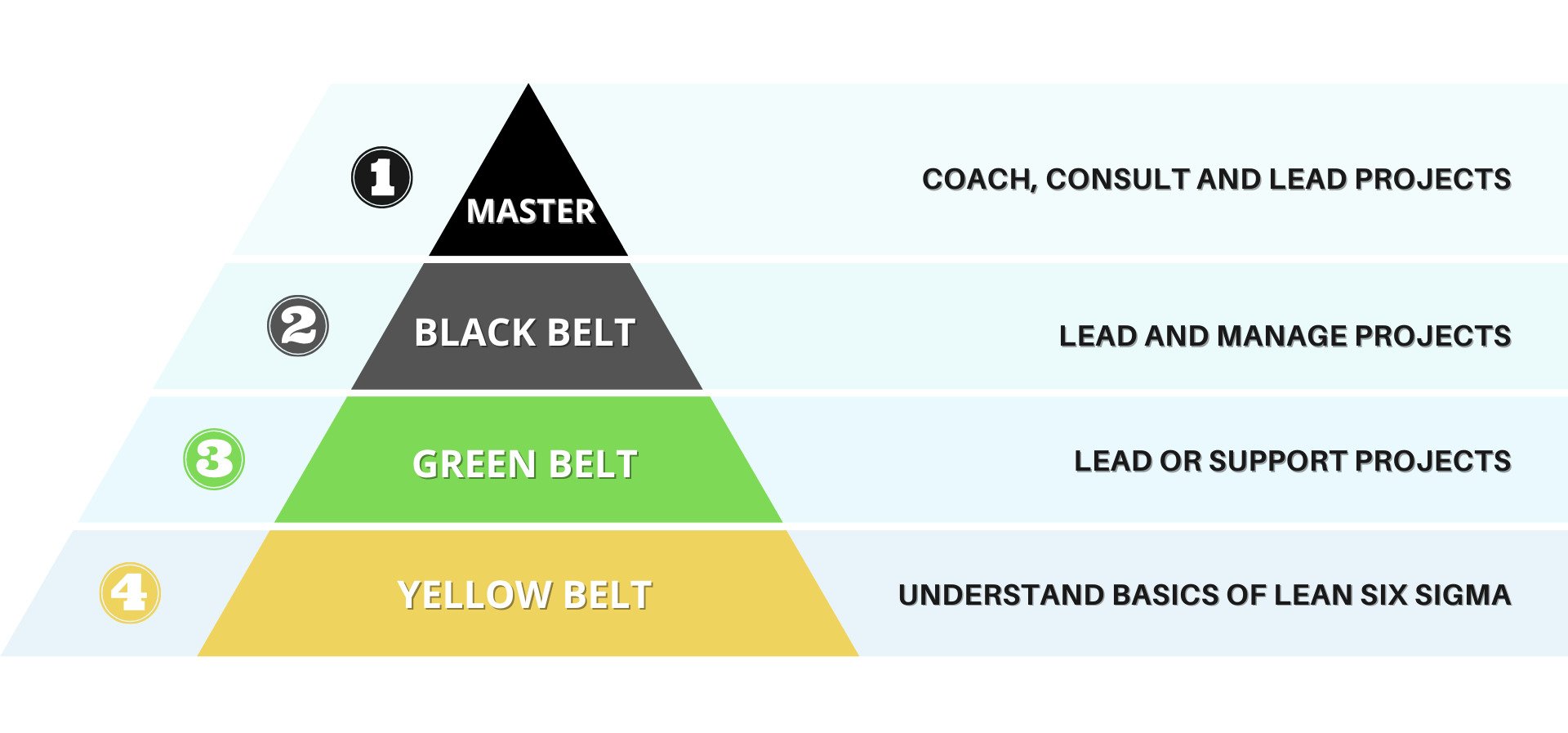

Sequence Of Six Sigma Belts

Six Sigma approaches identify process flaws using particular business data and then implement a precise plan of action to make the process as close to perfect as possible. Six Sigma has a hierarchical structure comparable to that of martial arts:

- Go lean six sigma white belt.

- Go lean six sigma yellow belt.

- Go lean six sigma green belt.

- Go lean six sigma black belt.

- Go lean six sigma master black belt.

Each belt provides different economic benefits to the holder and the teams with whom he or she works.

White Belt - For Beginners

A White Belt represents someone at the start of their Six Sigma journey and is quite simple to obtain, requiring only a single morning training session to become qualified.

Once obtained, White Belts can aid problem-solving teams that are part of larger projects but are not necessarily Six Sigma projects. White Belts have a solid understanding of Six Sigma methodology and the mindset that drives it.

Yellow Belt

Yellow Belts are often personnel who have completed the fundamental training in Six Sigma methodology and report to their project leader, who is normally a Green or Black Belt.

Yellow Belt holders concentrate on the process area under review and execute changes at ground level. Their involvement in a project is critical since they are a key component of the team with knowledge of the business sector being developed.

A Yellow Belt would help to produce 'process maps' utilizing their practical experience at the outset of a project and may be accountable for minor initiatives relevant to their work within the main objective.

Employees with such hands-on expertise are vital to any firm, and by undergoing structured training in Six Sigma methodology, they can acquire professional accreditation as well as access to a well-defined path to advancement within the Six Sigma hierarchy.

Green Belt

Green Belt is the next rung up in the Six Sigma system. An employee at the Green Belt level would, in addition to their other responsibilities, manage a process improvement team. Being a Green Belt is not a full-time job, but it takes up about 25–50% of their time.

Projects typically focus on their own work area or department, allowing them to apply their professional knowledge and practical business experience within the organization.

Once qualified, a Green Belt may be chosen by the management team to oversee a project. A Green Belt would need to know how to motivate a team; not all employees enthusiastically embrace the Six Sigma approach, and full team participation is critical to project success.

A Green Belt would be expected to acquire all essential data to be used in the project as the leader of the process team, as well as validate the measurement system. Leadership characteristics are essential for this function in order for the project to be a success.

Black Black

The Black Belt level is a natural progression from the Green Belt level, and holders will devote 100% of their time to Six Sigma initiatives. They oversee teams of Green, Yellow, and White Belts in a range of ongoing initiatives rather than focusing on just one.

Black Belt level needs significant leadership abilities as well as the ability to accurately convey the Six Sigma philosophy and principles. They play an important role in training lower-ranked Belts while receiving tutoring from Master Black Belts.

In addition to passion and business acumen, Black Belts must have technical aptitude in order to acquire appropriate data and analyze it regularly. They are required to provide real results for the firm rapidly and to explain each step of the process to the appropriate audience, whether that is corporate leaders or shop floor workers.

Master Black Belt

To advance from Black Belt to Master Black Belt, you must supervise the company's Six Sigma program, complete statistical duties, and coach Black Belts and Green Belts.

A Master Black Belt must be able to provide a comprehensive, high-level strategic picture of corporate improvements and communicate key data to top executives and departmental managers.

In addition to technical understanding, a good Master Black Belt should be able to disseminate such knowledge at all levels, from senior executives to shop floor workers. Ensure that Six Sigma procedures are followed on all projects and be able to explain why to staff who may not be completely involved with the system.

Typically, candidates must complete a real-world process improvement project as part of the certification process. This project allows individuals to demonstrate their capacity to generate substantial improvements in their organization by putting the Lean Six Sigma methodology and technologies they've learned to use.

Go Lean Six Sigma - FAQs

What Is Go Lean Six Sigma?

Go Lean Six Sigma is a methodology that combines the principles of Lean and Six Sigma to optimize processes, reduce waste, and enhance overall efficiency in organizations.

How Does Go Lean Six Sigma Differ From Traditional Six Sigma?

Go Lean Six Sigma integrates Lean principles, focusing not only on defect reduction but also on eliminating non-value-added activities, leading to a more comprehensive approach to process improvement.

What Are The Key Benefits Of Implementing Go Lean Six Sigma?

The benefits include improved productivity, reduced costs, enhanced customer satisfaction, and the establishment of a culture of continuous improvement within an organization.

Can Go Lean Six Sigma Be Applied To Any Industry?

Yes, Go Lean Six Sigma is versatile and applicable across various industries, including manufacturing, healthcare, finance, and service sectors.

What Are The Main Tools Used In Go Lean Six Sigma Projects?

Common tools include process mapping, value stream analysis, DMAIC (Define, Measure, Analyze, Improve, Control) methodology, and various statistical techniques.

Final Words

In the fast-paced realm of modern business, the significance of Go Lean Six Sigma cannot be overstated. As we conclude our exploration of this transformative methodology, it becomes evident that embracing Lean Six Sigma principles is not merely a choice; it is a strategic imperative.

The journey towards operational excellence and heightened performance is paved with the tools and insights provided by Go Lean Six Sigma. By cultivating a mindset of continuous improvement, organizations can not only survive but thrive, adapting to the ever-evolving demands of the market.

With Go Lean Six Sigma as a guiding force, businesses can confidently navigate the complexities of the contemporary landscape, achieving efficiency, reducing costs, and ensuring sustainable success for years to come.

Frazer Pugh

Author

Frazer Pugh is a distinguished expert in finance and business, boasting over 6 years of experience. Holding an MBA in Finance from Stanford University, Frazer's credentials underscore his authority and expertise in the field.

With a successful track record in executive roles and as a published author of influential articles on financial strategy, his insights are both deep and practical.

Beyond his professional life, Frazer is an avid traveler and culinary enthusiast, drawing inspiration from diverse cultures and cuisines.

His commitment in delivering trustworthy analysis and actionable advice reflects his dedication to shaping the world of finance and business, making a significant impact through his work.

Dexter Cooke

Reviewer

Dexter Cooke is an economist, marketing strategist, and orthopedic surgeon with over 20 years of experience crafting compelling narratives that resonate worldwide.

He holds a Journalism degree from Columbia University, an Economics background from Yale University, and a medical degree with a postdoctoral fellowship in orthopedic medicine from the Medical University of South Carolina.

Dexter’s insights into media, economics, and marketing shine through his prolific contributions to respected publications and advisory roles for influential organizations.

As an orthopedic surgeon specializing in minimally invasive knee replacement surgery and laparoscopic procedures, Dexter prioritizes patient care above all.

Outside his professional pursuits, Dexter enjoys collecting vintage watches, studying ancient civilizations, learning about astronomy, and participating in charity runs.

Latest Articles

Popular Articles