Industrial Foregoing Pump - Revolutionizing Industrial Fluid Management

One groundbreaking solution that has emerged in recent years is the Industrial Foregoing Pump. This advanced pumping system has revolutionized fluid management in industries, offering numerous benefits and transforming the way fluids are handled.

Author:Tyreece BauerReviewer:Gordon DickersonMay 30, 202328.5K Shares492.3K Views

Fluid management is a critical aspect of various industrial processes, ranging from manufacturing and mining to agriculture and energy production. Efficiently extracting, transporting, and utilizing fluids is essential for maximizing productivity and minimizing costs.

One groundbreaking solution that has emerged in recent years is the Industrial Foregoing Pump. This advanced pumping system has revolutionized fluid management in industries, offering numerous benefits and transforming the way fluids are handled.

What Is The Industrial Foregoing Pump?

The Industrial Foregoing Pump is a cutting-edge fluid extraction and transportation device developed for industrial applications. It is designed to efficiently collect, move, and store various types of fluids, including water, oil, chemicals, and gases.

Unlike traditional pumps, the Industrial Foregoing Pump incorporates innovative technologies that optimize fluid management processes, ensuring higher efficiency, reliability, and cost-effectiveness.

Industrial Foregoing Pump - Key Features And Components

The Industrial Foregoing Pump incorporates a range of cutting-edge features and components that set it apart from traditional pumping systems. Let's explore the intricacies of each feature and component, understanding how they contribute to the pump's exceptional performance and reliability.

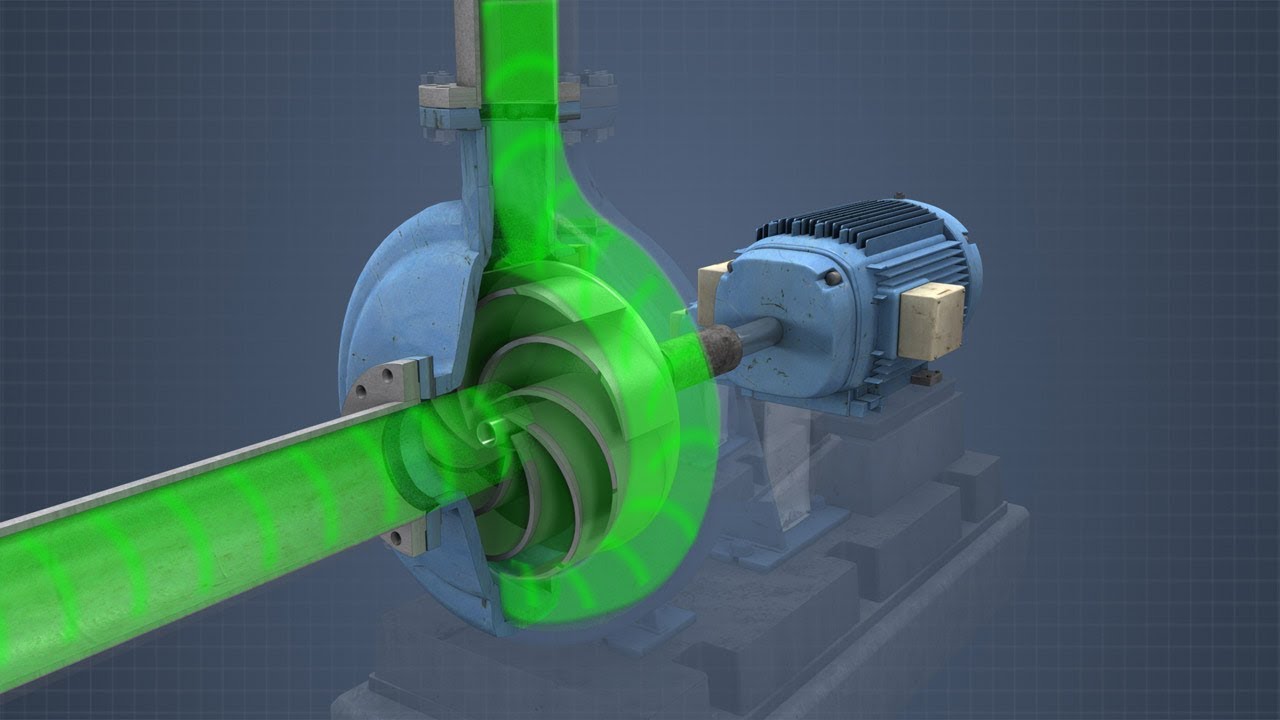

Advanced Pumping Mechanism

At the heart of the Industrial Foregoing Pump lies its advanced pumping mechanism. This mechanism employs high-performance motors, impellers, and valves to generate significant suction and pressure forces.

The result is an exceptionally efficient fluid extraction and transportation process, allowing industries to achieve higher throughput rates and quicker fluid transfer.

Versatile Fluid Compatibility

The Industrial Foregoing Pump is designed to handle a wide range of fluids, making it a versatile solution for various industries.

Whether it's water for irrigation, oil for extraction, or chemicals for manufacturing processes, this pump can effectively handle different fluid types without compromising performance or efficiency. The pump's design also ensures minimal contamination risks, making it suitable for applications requiring strict fluid purity.

Intelligent Control Systems

To enhance operational efficiency and user convenience, the Industrial Foregoing Pump incorporates intelligent control systems.

These systems utilize sensors, programmable logic controllers (PLCs), and advanced algorithms to monitor and optimize pump performance in real-time. Operators can easily adjust parameters, such as flow rate, pressure, and timing, to ensure precise fluid management tailored to their specific needs.

Durable And Low-Maintenance Construction

Industries demand equipment that can withstand harsh operating conditions and deliver consistent performance over extended periods.

The Industrial Foregoing Pump excels in this regard, featuring a robust construction and high-quality materials. Its components are designed to resist corrosion, erosion, and wear, reducing the need for frequent maintenance and replacement. This durability translates into long-term cost savings and improved operational reliability.

Industrial Foregoing Pump - Applications And Benefits

The Industrial Foregoing Pump finds applications in a wide range of industries, providing significant benefits to fluid management processes. Let's explore some of its primary applications and the advantages it offers in each scenario.

Mining And Quarrying

In the mining and quarrying industry, water is often required for various operations, such as dust suppression, equipment cooling, and ore processing.

The Industrial Foregoing Pump enables efficient water extraction from underground sources, such as wells or reservoirs, and facilitates its distribution throughout the mining site. By ensuring a reliable water supply, the pump enhances productivity, prolongs equipment lifespan, and improves overall operational safety.

Agriculture And Irrigation

Efficient irrigation systems are vital for agricultural productivity, ensuring crops receive the necessary water for growth and development. The Industrial Foregoing Pump revolutionizes irrigation by providing reliable water extraction from natural sources, such as rivers, lakes, or wells.

With its high flow rate and adjustable pressure control, the pump allows farmers to distribute water precisely, optimizing irrigation efficiency and reducing water wastage. This leads to improved crop yield, minimized resource consumption, and enhanced sustainability in agriculture.

Manufacturing And Processing

Manufacturing and processing plants rely on a consistent supply of fluids for various production stages. The Industrial Foregoing Pump streamlines fluid management in these facilities by automating fluid extraction, transportation, and storage processes.

With its intelligent control systems, the pump ensures precise delivery of fluids, minimizing human error and maximizing operational efficiency. Additionally, the pump's compatibility with diverse fluid types makes it suitable for handling chemicals, lubricants, and other industrial fluids with ease.

Energy And Utilities

The energy and utilities sector heavily relies on fluid management systems to extract, process, and transport fuels, such as oil and natural gas. The Industrial Foregoing Pump offers a reliable solution for these applications, providing efficient fluid extraction from underground or offshore sources.

Its high-performance pumping mechanism allows for rapid fluid transfer, enhancing operational efficiency in oil rigs, refineries, and power plants. By improving fluid management, the pump contributes to reduced downtime, increased energy output, and improved cost-effectiveness.

Industrial Foregoing Pump In Fluid Storage And Transportation

The Industrial Foregoing Pump plays a crucial role in fluid storage and transportation within various industries. With its efficient pumping mechanism and versatile capabilities, this pump ensures smooth and reliable fluid movement, optimizing the overall workflow.

When it comes to fluid storage, the Industrial Foregoing Pump offers impressive capacity and compatibility with different storage containers. It can efficiently transfer fluids from extraction points to storage tanks, minimizing the risk of leakage or contamination. The pump's intelligent control systems enable precise fluid level monitoring, ensuring optimal storage conditions and preventing overflows.

In terms of fluid transportation, the Industrial Foregoing Pump excels in its ability to move fluids over long distances and through complex pipelines. Its high-performance pumping mechanism generates substantial suction and pressure forces, allowing fluids to be transported efficiently and swiftly. Whether it's transferring water for irrigation or chemicals for industrial processes, this pump ensures timely delivery, minimizing delays and optimizing productivity.

Furthermore, the Industrial Foregoing Pump's adjustable flow rate and pressure control enable customized fluid transportation based on specific industry requirements. This flexibility allows industries to adapt to varying demand levels and optimize energy consumption during transportation, leading to cost savings and improved efficiency.

Environmental Benefits Of The Industrial Foregoing Pump

The Industrial Foregoing Pump not only offers significant advantages for industrial processes but also provides notable environmental benefits. Its innovative design and advanced features contribute to sustainable fluid management practices, reducing environmental impact and promoting conservation efforts.

One of the primary environmental benefits of the Industrial Foregoing Pump is its high energy efficiency. The pump's intelligent control systems optimize power consumption, ensuring that only the necessary energy is used during operation. By minimizing energy waste, the pump helps reduce greenhouse gas emissions and contributes to a greener industrial landscape.

Additionally, the Industrial Foregoing Pump's efficient fluid extraction and transportation processes lead to reduced resource consumption. With its advanced pumping mechanism, the pump can extract fluids from underground sources or reservoirs with minimal wastage. This efficiency translates into conservation of water resources and reduces the strain on natural ecosystems.

Moreover, the pump's compatibility with diverse fluid types allows for proper management of potentially hazardous substances. Industries can effectively handle and transport chemicals, oils, and other fluids, minimizing the risk of accidental spills or leaks that could harm the environment.

Centrifugal Pumps

Key Considerations For Implementing The Industrial Foregoing Pump In Industries

Implementing the Industrial Foregoing Pump in industrial settings requires careful consideration of several key factors to ensure successful integration and optimal performance. By addressing these considerations, industries can maximize the benefits offered by this advanced pumping system.

First and foremost, it is crucial to assess the specific fluid management requirements of the industry. Different sectors may have unique fluid characteristics, flow rates, and operational needs. Understanding these factors is essential in selecting the appropriate Industrial Foregoing Pump model with the necessary specifications to meet the industry's demands effectively.

Another key consideration is the infrastructure and pipeline system within the industrial facility. The Industrial Foregoing Pump's compatibility with existing infrastructure plays a vital role in seamless integration.

Evaluating the compatibility of the pump's connectors, valves, and fittings with the existing pipeline system ensures smooth fluid flow and minimizes the need for extensive modifications or replacements.

Maintenance and servicing requirements should also be taken into account. The Industrial Foregoing Pump's low-maintenance construction and durability contribute to reduced downtime and operational costs. However, regular maintenance schedules, including inspections, cleaning, and component replacements, should be established to ensure the pump's longevity and optimal performance.

Furthermore, it is essential to provide appropriate training for operators and maintenance personnel. Familiarity with the pump's control systems, safety protocols, and troubleshooting procedures ensures efficient operation and minimizes the risk of errors or accidents.

People Also Ask

Does The Industrial Foregoing Pump Have Variable Speed Control For Precise Fluid Management?

Yes, the Industrial Foregoing Pump offers variable speed control to allow precise fluid management based on specific requirements.

Can The Industrial Foregoing Pump Handle High-Viscosity Fluids?

Yes, the Industrial Foregoing Pump is designed to handle high-viscosity fluids efficiently with its powerful pumping mechanism.

What Is The Lifespan Of The Industrial Foregoing Pump?

The Industrial Foregoing Pump has a long lifespan due to its durable construction and resistance to corrosion and wear.

Is The Industrial Foregoing Pump Compatible With Remote Monitoring And Control Systems?

Yes, the Industrial Foregoing Pump can be integrated with remote monitoring and control systems for enhanced operational efficiency.

Conclusion

The Industrial Foregoing Pump has undoubtedly revolutionized fluid management in industrial settings. With its advanced pumping mechanism, versatility, intelligent control systems, and durable construction, this pump delivers unparalleled performance and efficiency.

Whether it's in mining, agriculture, manufacturing, or energy production, the Industrial Foregoing Pump offers substantial benefits, ranging from increased productivity and cost savings to enhanced operational reliability and sustainability.

As industries continue to evolve and seek innovative solutions, the Industrial Foregoing Pump stands out as a game-changer in the field of fluid management, ensuring a more efficient and sustainable future.

Jump to

What Is The Industrial Foregoing Pump?

Industrial Foregoing Pump - Key Features And Components

Industrial Foregoing Pump - Applications And Benefits

Industrial Foregoing Pump In Fluid Storage And Transportation

Environmental Benefits Of The Industrial Foregoing Pump

Key Considerations For Implementing The Industrial Foregoing Pump In Industries

People Also Ask

Conclusion

Tyreece Bauer

Author

A trendsetter in the world of digital nomad living, Tyreece Bauer excels in Travel and Cybersecurity. He holds a Bachelor's degree in Computer Science from MIT (Massachusetts Institute of Technology) and is a certified Cybersecurity professional.

As a Digital Nomad, he combines his passion for exploring new destinations with his expertise in ensuring digital security on the go. Tyreece's background includes extensive experience in travel technology, data privacy, and risk management in the travel industry.

He is known for his innovative approach to securing digital systems and protecting sensitive information for travelers and travel companies alike. Tyreece's expertise in cybersecurity for mobile apps, IoT devices, and remote work environments makes him a trusted advisor in the digital nomad community.

Tyreece enjoys documenting his adventures, sharing insights on staying secure while traveling and contributing to the digital nomad lifestyle community.

Gordon Dickerson

Reviewer

Gordon Dickerson, a visionary in Crypto, NFT, and Web3, brings over 10 years of expertise in blockchain technology.

With a Bachelor's in Computer Science from MIT and a Master's from Stanford, Gordon's strategic leadership has been instrumental in shaping global blockchain adoption. His commitment to inclusivity fosters a diverse ecosystem.

In his spare time, Gordon enjoys gourmet cooking, cycling, stargazing as an amateur astronomer, and exploring non-fiction literature.

His blend of expertise, credibility, and genuine passion for innovation makes him a trusted authority in decentralized technologies, driving impactful change with a personal touch.

Latest Articles

Popular Articles