P3 Fusion Calculator - The Importance Of Proper Calibration

The P3 Fusion Calculator is a powerful tool that has been developed for use in the field of engineering. It is a software application that is used to calculate the fusion time required to join two or more pieces of plastic using a hot plate fusion process. The P3 Fusion Calculator is a valuable resource for engineers who are involved in designing and building plastic products.

Author:Tyreece BauerReviewer:Gordon DickersonMay 15, 202359.7K Shares1M Views

The P3 Fusion Calculatoris a powerful tool that has been developed for use in the field of engineering. It is a software application that is used to calculate the fusion time required to join two or more pieces of plastic using a hot plate fusion process. The P3 Fusion Calculator is a valuable resource for engineers who are involved in designing and building plastic products.

What Is Hot Plate Fusion?

Hot plate fusion is a technique used to join two or more pieces of plastic together. It involves heating the surfaces of the plastic to be joined until they melt and then pressing them together to form a bond. Hot plate fusion is commonly used in the manufacture of plastic products such as pipes, tanks, and other industrial components.

The hot plate fusion process is a complex process that requires precise temperature control and timing. The P3 Fusion Calculator simplifies this process by providing engineers with a tool that can accurately calculate the fusion time required for a given set of parameters.

How Does The P3 Fusion Calculator Work?

The P3 Fusion Calculator is a software application that uses a sophisticated algorithm to calculate the fusion time required for a given set of parameters. The user enters the parameters of the hot plate fusion process, such as the size and thickness of the plastic pieces to be joined, the temperature of the hot plate, and the pressure applied during the fusion process.

Once the parameters are entered, the P3 Fusion Calculator uses its algorithm to calculate the fusion time required for the process. The user can then adjust the parameters as needed to achieve the desired fusion time.

Features Of The P3 Fusion Calculator

The P3 Fusion Calculator has several features that make it a valuable tool for engineers. Some of the key features of the P3 Fusion Calculator include:

Accuracy

The P3 Fusion Calculator uses a sophisticated algorithm to calculate the fusion time required for a given set of parameters.

This algorithm takes into account a wide range of factors that can affect the fusion process, such as the size and thickness of the plastic pieces to be joined, the temperature of the hot plate, and the pressure applied during the fusion process. This results in highly accurate fusion time calculations.

Ease Of Use

The P3 Fusion Calculator is designed to be easy to use. The user interface is intuitive and easy to navigate, and the software provides clear instructions on how to use the tool.

Flexibility

The P3 Fusion Calculator is a flexible tool that can be used to calculate fusion times for a wide range of plastic materials and hot plate fusion parameters. This makes it a valuable resource for engineers who work with a variety of plastic materials.

Cost-Effective

The P3 Fusion Calculator is a cost-effective tool that can save engineers time and money by streamlining the hot plate fusion process. By accurately calculating the fusion time required for a given set of parameters, engineers can reduce the number of trial-and-error attempts required to achieve the desired fusion results.

Benefits Of The P3 Fusion Calculator

The P3 Fusion Calculator offers several benefits to engineers who work with hot plate fusion processes. Some of the key benefits of the P3 Fusion Calculator include:

Improved Efficiency

The P3 Fusion Calculator can help engineers improve the efficiency of the hot plate fusion process. By accurately calculating the fusion time required for a given set of parameters, engineers can reduce the number of trial-and-error attempts required to achieve the desired fusion results.

Improved Product Quality

The P3 Fusion Calculator can help engineers improve the quality of the plastic products they design and build. By accurately calculating the fusion time required for a given set of parameters, engineers can ensure that the fusion process is performed correctly and that the resulting bond is strong and durable.

Reduced Waste

By streamlining the hot plate fusion process, the P3 Fusion Calculator can help engineers reduce waste. By accurately calculating the fusion time required for a given set of parameters, engineers can reduce the number of failed attempts and reduce the amount of plastic that is wasted during the fusion process.

Applications Of The P3 Fusion Calculator

The P3 Fusion Calculator has a wide range of applications in the field of engineering. Some of the key applications of the P3 Fusion Calculator include:

Plastic Product Design

The P3 Fusion Calculator is a valuable tool for engineers who are involved in designing and building plastic products. By accurately calculating the fusion time required for a given set of parameters, engineers can ensure that the hot plate fusion process is performed correctly and that the resulting bond is strong and durable.

Quality Control

The P3 Fusion Calculator can be used in quality control applications to ensure that the hot plate fusion process is performed correctly. By using the P3 Fusion Calculator to calculate the fusion time required for a given set of parameters, engineers can ensure that the fusion process is performed consistently and that the resulting bonds are strong and durable.

Process Optimization

The P3 Fusion Calculator can be used to optimize the hot plate fusion process. By using the P3 Fusion Calculator to calculate the fusion time required for a given set of parameters, engineers can adjust the parameters as needed to achieve the desired fusion time. This can help engineers optimize the hot plate fusion process for maximum efficiency and effectiveness.

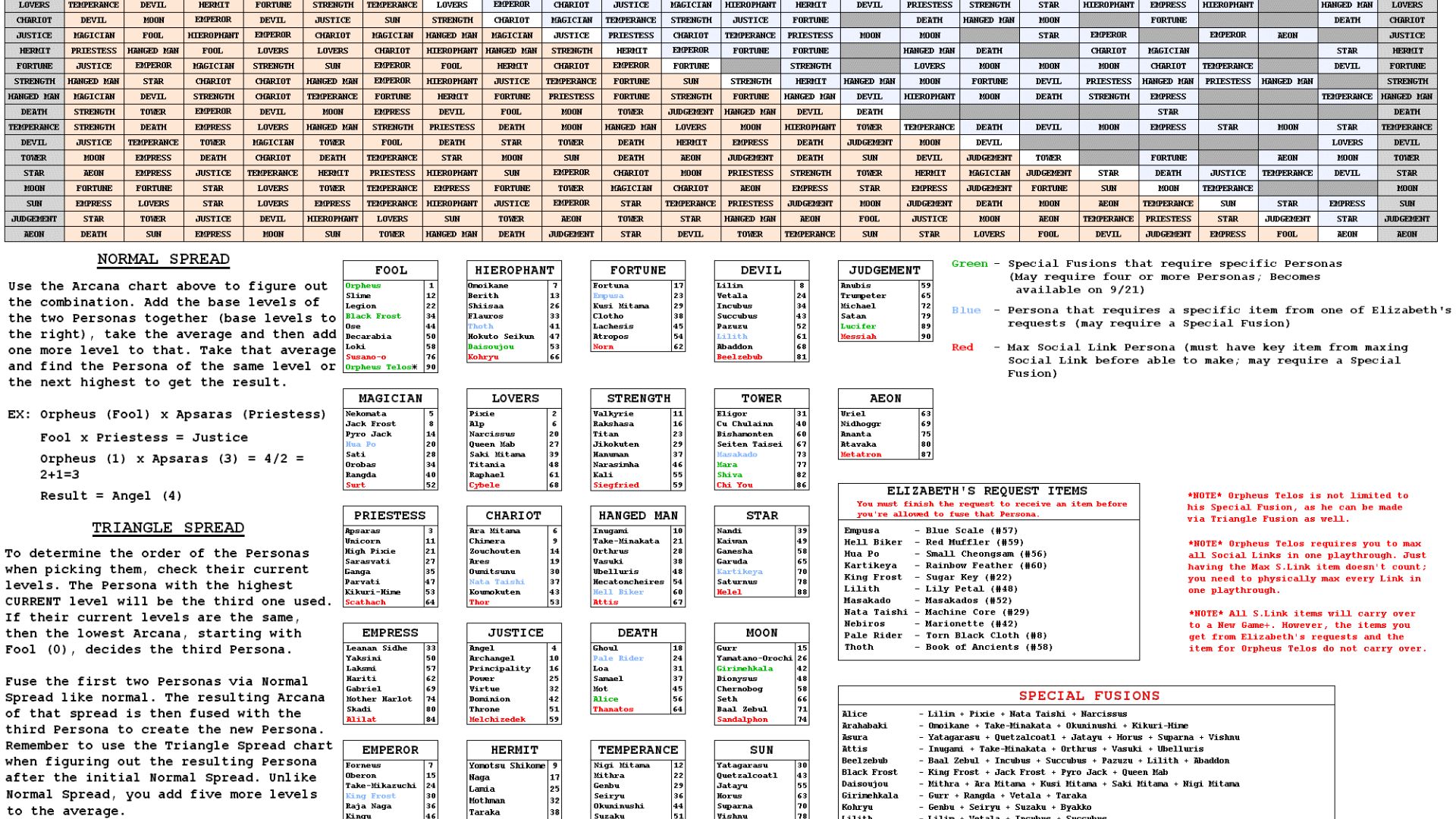

Let's Play Persona 3 FES The Journey Episode 12 Fusion Tutorial

Using The P3 Fusion Calculator For Different Types Of Plastics

The P3 Fusion Calculator is a versatile tool that can be used for different types of plastics. Each type of plastic has its own unique properties that affect the hot plate fusion process. The P3 Fusion Calculator takes into account these properties and calculates the fusion time required for a given set of parameters.

Different types of plastics have different melting points, which means that the fusion time required for each type of plastic will be different. By using the P3 Fusion Calculator, engineers can accurately calculate the fusion time required for a given type of plastic and adjust the parameters as needed to achieve the desired result.

Additionally, the P3 Fusion Calculator can be used to determine the appropriate fusion pressure for different types of plastics. Different types of plastics require different fusion pressures, and the P3 Fusion Calculator takes this into account when calculating the fusion time required for a given set of parameters.

Importance Of Proper Calibration Of The P3 Fusion Calculator

Proper calibration of the P3 Fusion Calculator is essential for accurate results. Calibration ensures that the P3 Fusion Calculator is functioning correctly and that the fusion time and pressure calculations are accurate.

To calibrate the P3 Fusion Calculator, engineers need to use a calibration standard with known properties. The calibration standard should have a melting point that is close to the melting point of the plastic being used. By fusing the calibration standard and measuring the fusion time and pressure, engineers can verify that the P3 Fusion Calculator is functioning correctly.

P3 Fusion Calculator For Large-Scale Production

The P3 Fusion Calculator is a powerful tool for large-scale production of plastic products. Large-scale production requires precise control over the fusion process to ensure consistent results and reduce waste. The P3 Fusion Calculator can help achieve this by accurately calculating the fusion time and pressure required for a given set of parameters.

One of the key advantages of the P3 Fusion Calculator for large-scale production is its ability to calculate the fusion time and pressure for large batches of plastic parts. This allows engineers to optimize the fusion process and reduce the time required for production.

P3 Fusion Calculator V/S Traditional Fusion Methods

The P3 Fusion Calculator offers several advantages over traditional fusion methods. Traditional fusion methods typically rely on manual adjustments and trial and error to achieve the desired fusion time and pressure. This can be time-consuming and lead to inconsistent results.

In contrast, the P3 Fusion Calculator uses a scientific approach to calculate the fusion time and pressure required for a given set of parameters. This approach is more accurate and reliable than traditional fusion methods, which can help reduce waste and improve product quality.

Additionally, the P3 Fusion Calculator offers greater flexibility than traditional fusion methods. The P3 Fusion Calculator can be used with different types of plastics and can be adjusted to achieve the desired fusion time and pressure for a specific application. This makes the P3 Fusion Calculator a more versatile tool than traditional fusion methods.

People Also Ask

Can The P3 Fusion Calculator Be Used With Non-Plastic Materials?

No, the P3 Fusion Calculator is specifically designed for use with plastic materials.

How Long Does It Take To Calibrate The P3 Fusion Calculator?

Calibrating the P3 Fusion Calculator typically takes 30 minutes to an hour.

What Is The Warranty On The P3 Fusion Calculator?

The warranty on the P3 Fusion Calculator varies based on the specific model and manufacturer.

Can The P3 Fusion Calculator Be Used For Outdoor Applications?

Yes, the P3 Fusion Calculator can be used for outdoor applications, as long as it is protected from moisture and other environmental factors.

Conclusion

The P3 Fusion Calculator is a powerful tool that can help engineers improve the efficiency and effectiveness of the hot plate fusion process. By accurately calculating the fusion time required for a given set of parameters, the P3 Fusion Calculator can help engineers reduce waste, improve product quality, and streamline the hot plate fusion process.

Jump to

What Is Hot Plate Fusion?

How Does The P3 Fusion Calculator Work?

Features Of The P3 Fusion Calculator

Benefits Of The P3 Fusion Calculator

Applications Of The P3 Fusion Calculator

Using The P3 Fusion Calculator For Different Types Of Plastics

Importance Of Proper Calibration Of The P3 Fusion Calculator

P3 Fusion Calculator For Large-Scale Production

P3 Fusion Calculator V/S Traditional Fusion Methods

People Also Ask

Conclusion

Tyreece Bauer

Author

A trendsetter in the world of digital nomad living, Tyreece Bauer excels in Travel and Cybersecurity. He holds a Bachelor's degree in Computer Science from MIT (Massachusetts Institute of Technology) and is a certified Cybersecurity professional.

As a Digital Nomad, he combines his passion for exploring new destinations with his expertise in ensuring digital security on the go. Tyreece's background includes extensive experience in travel technology, data privacy, and risk management in the travel industry.

He is known for his innovative approach to securing digital systems and protecting sensitive information for travelers and travel companies alike. Tyreece's expertise in cybersecurity for mobile apps, IoT devices, and remote work environments makes him a trusted advisor in the digital nomad community.

Tyreece enjoys documenting his adventures, sharing insights on staying secure while traveling and contributing to the digital nomad lifestyle community.

Gordon Dickerson

Reviewer

Gordon Dickerson, a visionary in Crypto, NFT, and Web3, brings over 10 years of expertise in blockchain technology.

With a Bachelor's in Computer Science from MIT and a Master's from Stanford, Gordon's strategic leadership has been instrumental in shaping global blockchain adoption. His commitment to inclusivity fosters a diverse ecosystem.

In his spare time, Gordon enjoys gourmet cooking, cycling, stargazing as an amateur astronomer, and exploring non-fiction literature.

His blend of expertise, credibility, and genuine passion for innovation makes him a trusted authority in decentralized technologies, driving impactful change with a personal touch.

Latest Articles

Popular Articles